The cost of cooking oil has risen dramatically in recent years, forcing foodservice operators— from restaurants and hotels to casinos and bakeries—to find ways to manage these rising expenses without compromising the quality of their fried foods. They must opt for innovative solutions to reduce oil consumption while maintaining product excellence.

This is where Frylow, an award-winning oil-saving technology company, offers a great solution. Frylow has developed an innovative device to enhance the performance of cooking oil in commercial deep fryers.

The premium fryer oil-extending device can be easily placed in any deep fryer and uses a natural, photo-catalytic technology to slow down oxidation and reduce oil viscosity. It introduces a negative ionic charge that changes the polarity of oil molecules, making food naturally repel the oil rather than absorb it. By doing this, Frylow forces the food to cook from the inside out instead of the outside in, allowing it to retain more natural moisture. This process leads to a more efficient, thermally optimized frying process, resulting in lighter, healthier, and more flavorful deep-fried food items.

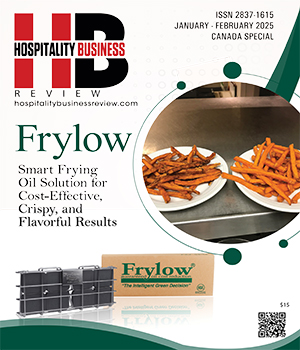

For example, sweet potato fries cooked with Frylow retain their vibrant color and natural sweetness, while those fried conventionally may turn soggy and greasy, masking their inherent flavor. The device enables frying at lower temperatures without sacrificing speed or quality, producing consistently crispy and flavorful results across all menu items. Chefs worldwide reveal that it helps preserve the distinct flavors of different dishes, even in high-volume kitchens, where cross-contamination of flavors can be a concern. In addition, the extended oil life and reduced frequency of oil changes allow businesses to significantly cut their operating costs and save tens of thousands of dollars over time through less oil consumption.

“Our Frylow technology can help restaurants save up to 50 percent or more on oil costs alone. The savings accumulate quickly, with many clients reporting a return on investment in six months or less,” says Chris Huxtable, president.

Beyond cost savings and food quality, Frylow helps businesses operate more sustainably. By reducing oil consumption, the device decreases the need for plastic oil containers, cardboard packaging, and waste oil disposal—critical issues in the food service industry. It also enables kitchens to lower fryer temperatures by up to 25°F, saving energy and reducing the carbon footprint of frying operations. Moreover, the ability to fry at lower temperatures results in less smoke and a healthier working environment for kitchen staff.

These sweet potato fries were cooked 5 minutes apart in the same oil. Without Frylow (left) and with Frylow (right), showing the difference Frylow can make within minutes of installation.

Easy Deployment and Maintenance

What makes Frylow more appealing is its ability to easily integrate with a wide range of fryers. Its FL-25 model is ideal for fryers holding 40 to 50 pounds of oil, while the FL-40 model is suitable for the higher oil capacity for larger fryers used in highvolume kitchens or specialized food environments like casinos or bakeries.

The onboarding process is straightforward and efficient, typically consisting of a 30-minute Zoom call or an in-person meeting. During this session, clients are trained on how to use the easy-to-operate unit. They are also educated on key factors like when to change the oil and the ideal cooking temperatures. While most restaurants typically cook between 350°F and 365°F, Frylow users can cook at or around 340°F with the same cook times or faster.

Our technology can help restaurants save up to 50 percent or more on oil costs alone. The savings accumulate quickly, with many clients reporting a return on investment in six months or less

At the Peak of Quality and Excellence

Developed in Japan over two decades ago, the device is still manufactured to the highest quality standards in Japanese manufacturing, ensuring its robustness and longevity. The five-year warranty signifies its confidence in the quality and reliability of the product.

The evidence of Frylow’s quality comes from well-known clients who installed the device and tracked guest feedback from the time of installation. They observed a noticeable shift in key metrics, like a drastic reduction in returned deep-fried items or improved positive reviews of deep-fried foods. Similarly, many other businesses have seen comparable improvements. The full impact of the technology is best highlighted through the success stories of companies that have implemented it.

A multi-location restaurant chain in Ontario, Canada, saved over $83,000 in oil costs and eliminated the need for 3,600 plastic jugs after implementing Frylow in their fryers for a period of three years. These savings were achieved even before the rise in oil prices brought on by the pandemic, highlighting the device’s value as a long-term investment.

Another notable example is a large hotel chain that reduced its oil consumption by 45 percent, enabling the kitchens to improve their operational efficiency while maintaining food quality. These real-world examples underscore its role in helping businesses save money, reduce waste, and improve food quality.

Frylow’s innovative technology has earned it the prestigious Master Chef Seal of Excellence from the Master Chefs Institute in Florida. In a double-blind, side-by-side test using new oil in both fryers, the device outperformed oil without Frylow across all categories, showcasing its superior performance and earning the trust of top chefs worldwide. This recognition truly underscores why Frylow is an essential tool for any business looking to modernize and optimize its frying operations. It highlights the product’s value and effectiveness in improving operational efficiency and food quality.

Since 2003, Frylow has been saving money for frying oil costs for restaurants, hotels, cruise ships, and commercial kitchens. With its industry-leading fry oil saver, it remains dedicated to helping clients save money, cook safer food, and reduce their carbon footprint.

Thank you for Subscribing to Hospitality Business Review Weekly Brief